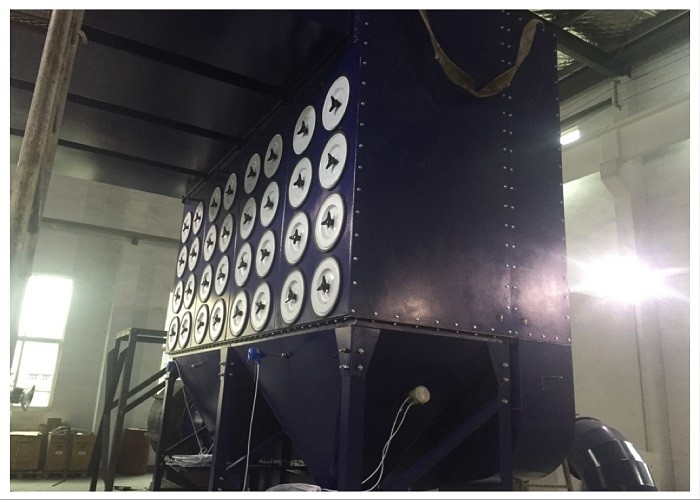

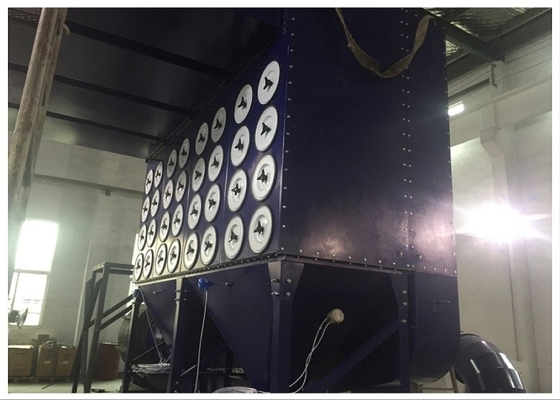

Carbon Steel Industrial Dust Removal System Shot Blasting Sandblasting Process

-

High Light

room dust collector

,industrial dust control systems

-

NameCartridge Dust Collector,Industrial Dust Collector Shot Blasting Air Filter Cartridge,Gas Turbine Round Dust Collector Filter Cartridge For Power Plant

-

MaterialCarbon Steel

-

Efficiency99%

-

Filter Area1344㎡

-

Air Flow18030-43272CMH

-

Power15-20Kw

-

ApplicationGrinding, Laser Cutting, Machining, Mixing, Polishing, Welding, Wood Working, Bulk Powder, Composites Machining, Powder Coating.

-

Place of OriginCHINA

-

Brand NameAUZOER

-

CertificationISO

-

Model NumberCDC-64-4

-

Minimum Order Quantity1 unit

-

PriceNegotiable

-

Packaging DetailsWooden cases package

-

Delivery Time45 days

-

Payment TermsT/T(Negotiable)

-

Supply Ability300 units per year

Carbon Steel Industrial Dust Removal System Shot Blasting Sandblasting Process

CDC Downward Flow Cartridge Dust Collectors

The particles released during manufacturing processes are hazardous to both worker and equipment health, quickly leading to a number of problems if particles are not captured by dust collection equipment and filtered from facility air. Dust collection addresses this problem by drawing contaminated air through a filter or separator, trapping harmful particles and releasing cleaner air into the atmosphere or back onto the work floor.

All of these collectors are not the only part of Reliable Air Quality that will make a difference in your building. They help clean up your facility environment, we also provide air and electric powered portable and central Industrial vacuum units for general clean up and housekeeping issues your plant might be facing.

| Model | Dimension(mm) | Modular (pcs) | Filter Area(㎡) | Pulse Valves | Filter Cartridge QTY(pcs) | G.W.(KG) | ||||

| Length | Width | Height | Polyester | Paper | Size | QTY(pcs) | ||||

| CDC1-1 | 1670 | 635 | 1366 | 1 | 9.4 | 23 | 3/4" | 1 | 1 | 473 |

| CDC2-2 | 1670 | 635 | 1860 | 1 | 18.8 | 46 | 2 | 2 | 633 | |

| CDC3-3 | 1670 | 635 | 2315 | 1 | 28.2 | 69 | 3 | 3 | 748 | |

| CDC8-2 | 1014 | 2150 | 2520 | 1 | 75 | 168 | 1" | 4 | 8 | 925 |

| CDC12-3 | 1014 | 2150 | 3520 | 1 | 112 | 252 | 6 | 12 | 1216 | |

| CDC16-4 | 1014 | 2150 | 3970 | 1 | 150 | 336 | 8 | 16 | 1280 | |

| CDC18-3 | 1514 | 2150 | 3520 | 1 | 170 | 378 | 9 | 16 | 1510 | |

| CDC24-3 | 2018 | 2150 | 3520 | 2 | 225 | 504 | 12 | 24 | 1865 | |

| CDC32-4 | 2018 | 2150 | 3970 | 2 | 300 | 672 | 16 | 32 | 2235 | |

| CDC36-3 | 3020 | 2150 | 3520 | 3 | 338 | 756 | 18 | 36 | 2615 | |

| CDC48-4 | 3020 | 2150 | 3970 | 3 | 451 | 1008 | 24 | 48 | 3185 | |

| CDC48-3 | 4023 | 2150 | 3520 | 4 | 451 | 1008 | 24 | 48 | 3450 | |

| CDC64-4 | 4023 | 2150 | 3970 | 4 | 601 | 1344 | 32 | 64 | 4070 | |

| CDC60-3 | 5026 | 2150 | 3520 | 5 | 564 | 1260 | 30 | 60 | 4430 | |

| CDC72-3 | 6030 | 2150 | 3520 | 6 | 676 | 1512 | 36 | 72 | 4830 | |

| CDC80-4 | 5026 | 2150 | 3970 | 5 | 752 | 1680 | 40 | 80 | 5085 | |

| CDC96-4 | 6030 | 2150 | 3970 | 6 | 902 | 2016 | 48 | 96 | 6070 | |

| CDC112-4 | 7040 | 2150 | 3970 | 7 | 1052 | 2352 | 56 | 112 | 7040 | |

| CDC128-4 | 8050 | 2150 | 3970 | 8 | 1203 | 2688 | 64 | 128 | 8000 | |

![]()

Design Features

Modular design, free assembly, accurate processing technology. Mass production, quality control, can greatly shorten the delivery time.

![]()

Through the air flow simulation optimization, shell strength optimization to ensure the efficient and safe operation of the dust collector.

![]()

![]()

Working Principles

The negative pressure airflow generated by the draught fan shall enter into the flow sinking device through the inlet of the dust remover. After the dust particles collide with the guide plate, the large particles will sink first, and the dust mixture containing tiny particles shall be filtered and separated by the separation effect of the filter element in the dust removal chamber. when the dust goes through the filter element, it will be hindered on the surface of the filter element. When the hindered smoke dust constantly deposit on the surface of the filter element, the differeintal pressure between the interior and exterior of the filter element will keep on enlarging. When the differential pressure reaches the preset value, the magnetic valve controlling the compressed air shall be released to eject the compressed air in the air package from the outlet of the ejecting pipe. As induced by the Venturi, the ambient air as much as several times of the primary wind shall be sprayed to the surface of the filter element, under the high pressure air flow, the dust particles deposited on the filter element will break away from the surface of the filter element and fall into the ash drum, so that the surface of the entire filter element can be cleaned.

CDC dust removal efficiency is high, up to 99.9%, suitable for all kinds of industrial and mining enterprises and other industries dust control and recycling.